The evolution of fertilizer granulation equipment has significantly transformed organic production practices. As the demand for sustainable agriculture intensifies, innovative technologies are emerging to enhance efficiency and quality in fertilizer manufacturing. This article delves into the critical role that advanced granulation equipment plays in optimizing organic fertilizers.

Click to find more about Fertilizer granulation equipment for organic production.

The Role of Fertilizer Granulation Equipment in Organic Production

Fertilizer granulation equipment is pivotal for producing high-quality organic fertilizers that meet stringent agricultural standards. By converting raw materials into uniform granules, this technology ensures better nutrient release and improved soil health. The precision offered by modern granulators minimizes waste and maximizes resource utilization, which is essential for sustainable farming practices. Furthermore, these machines facilitate scalability, allowing producers to adjust output according to market demands while maintaining product integrity.

Xincheng: A Leader in Fertilizer Technology Innovation

Xincheng stands at the forefront of developing cutting-edge fertilizer production solutions tailored specifically for organic applications. With a commitment to quality-focused B2B partnerships, Xincheng integrates advanced engineering with user-friendly designs to enhance operational efficiency. Their state-of-the-art facilities employ rigorous testing protocols ensuring that every piece of equipment meets international standards before reaching clients. Through continuous research and development efforts, Xincheng remains dedicated to pushing the boundaries of what is possible within the realm of fertilizer technology.

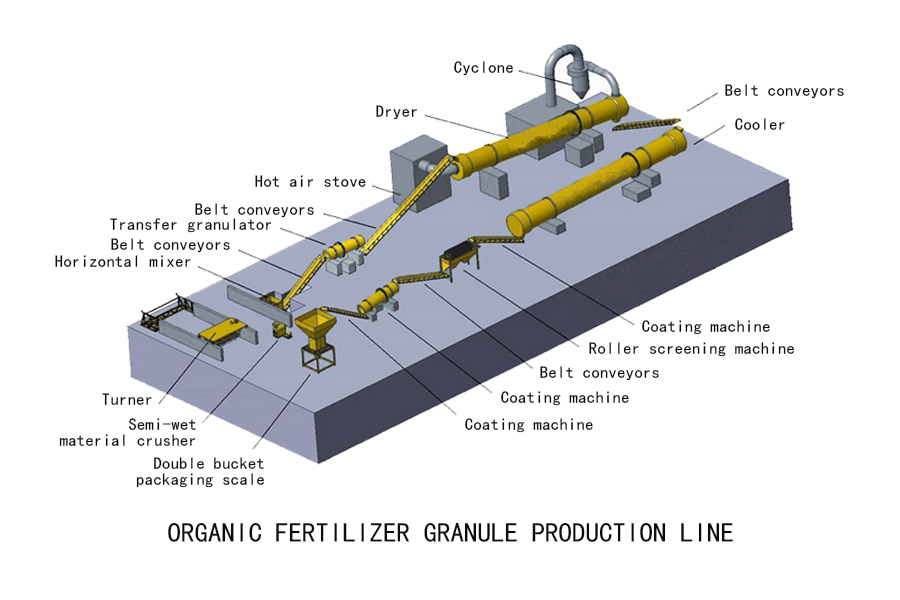

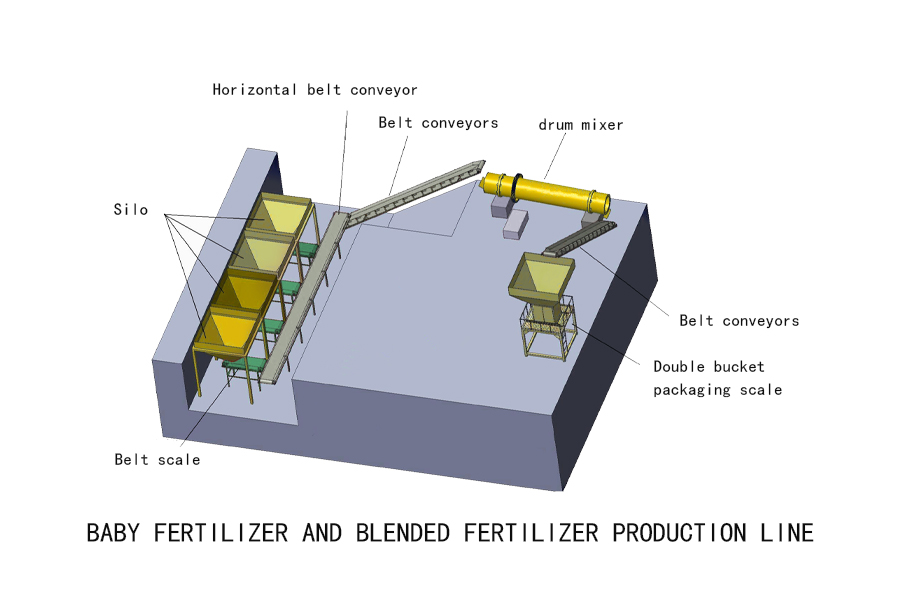

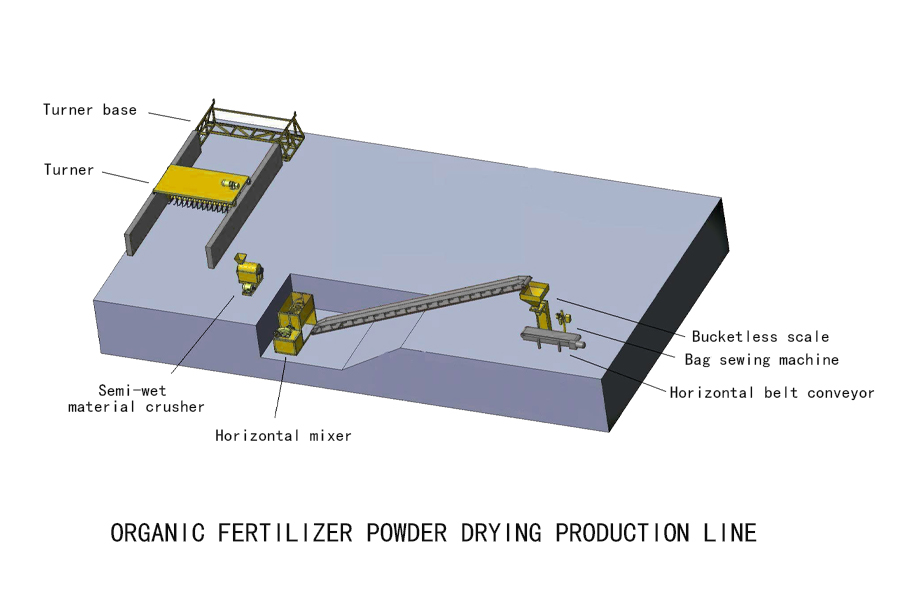

Understanding Organic Fertilizer Processing Lines

An effective Organic fertilizer processing line encompasses various stages from raw material preparation through final product packaging. Each phase requires specialized machinery designed to handle different types of inputs while preserving their nutritional value throughout processing. Advanced systems enable seamless integration between grinding, mixing, pelletizing, and drying processes—ensuring consistency and reliability in end products. Moreover, automation features reduce labor costs while enhancing safety measures within production environments.

Conclusion: The Future Landscape of Organic Production with Enhanced Granulation Equipment

The advancements in fertilizer granulation equipment are reshaping how we approach organic production today and into the future. By investing in high-quality machinery like those developed by industry leaders such as Xincheng, producers can achieve greater sustainability without compromising on performance or efficacy. Ultimately, embracing these innovations will not only benefit individual businesses but also contribute positively towards global agricultural practices aimed at fostering environmental stewardship.