Are you curious about the latest advancements in manufacturing technology? Well, let me introduce you to the world of smart manufacturing and its impact on industries. Smart manufacturing is revolutionizing traditional production methods by incorporating advanced technologies such as artificial intelligence, robotics, and data analytics. In this article, we will explore how smart manufacturing is transforming businesses in New Hampshire.

Click to find more about impact smart manufacturing.

The Benefits of Smart Manufacturing

Smart manufacturing has numerous benefits for businesses. By leveraging cutting-edge technologies, companies can optimize their production processes, improve efficiency, reduce costs, and enhance product quality. With real-time data analysis and predictive maintenance systems, manufacturers can identify potential issues before they occur and prevent costly downtime. Additionally, automation through robotics enables faster production cycles while ensuring precision and consistency.

JVTECH: Pioneering Smart Manufacturing Solutions

In New Hampshire’s thriving industrial landscape, JVTECH stands out as a leader in providing innovative smart manufacturing solutions. This company specializes in developing customized software platforms that integrate seamlessly with existing machinery to enable intelligent automation. Their state-of-the-art systems empower manufacturers to monitor operations remotely and make informed decisions based on real-time data insights.

By implementing JVTECH’s solutions into their workflows, businesses gain a competitive edge by streamlining operations and maximizing productivity. The integration of artificial intelligence algorithms allows machines to learn from patterns over time and continuously optimize performance without human intervention.

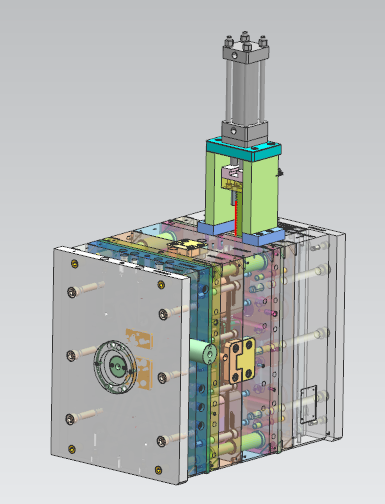

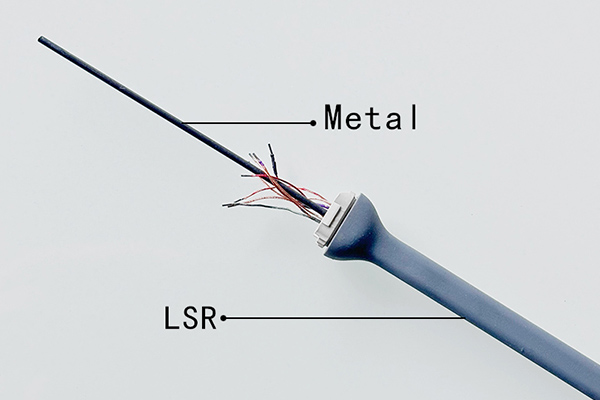

The Power of LSR Injection Molds

An essential component within smart manufacturing is the utilization of Liquid Silicone Rubber (LSR) injection molds. These molds are designed with precision to produce high-quality silicone-based products efficiently. lsr injection molding offers several advantages over traditional methods including shorter cycle times, reduced material waste due to precise dosing control capabilities, improved part quality, and increased design flexibility.

Manufacturers in New Hampshire are embracing LSR injection molds to create a wide range of products such as medical devices, automotive components, and consumer goods. The ability to produce complex shapes with tight tolerances makes LSR injection molding an ideal choice for industries that require precision engineering.

The Future of Smart Manufacturing

The impact of smart manufacturing is undeniable. As technology continues to advance at an unprecedented pace, businesses in New Hampshire must embrace these innovations to stay competitive in the global market. By adopting smart manufacturing practices and partnering with companies like JVTECH, manufacturers can unlock new levels of efficiency, productivity, and profitability.

In conclusion, smart manufacturing has revolutionized traditional production methods by incorporating advanced technologies. In New Hampshire’s industrial landscape, companies like JVTECH are leading the way in providing innovative solutions that optimize operations through intelligent automation. Additionally, the utilization of LSR injection molds further enhances product quality and design flexibility. Embracing these advancements is crucial for businesses looking to thrive in today’s fast-paced world.